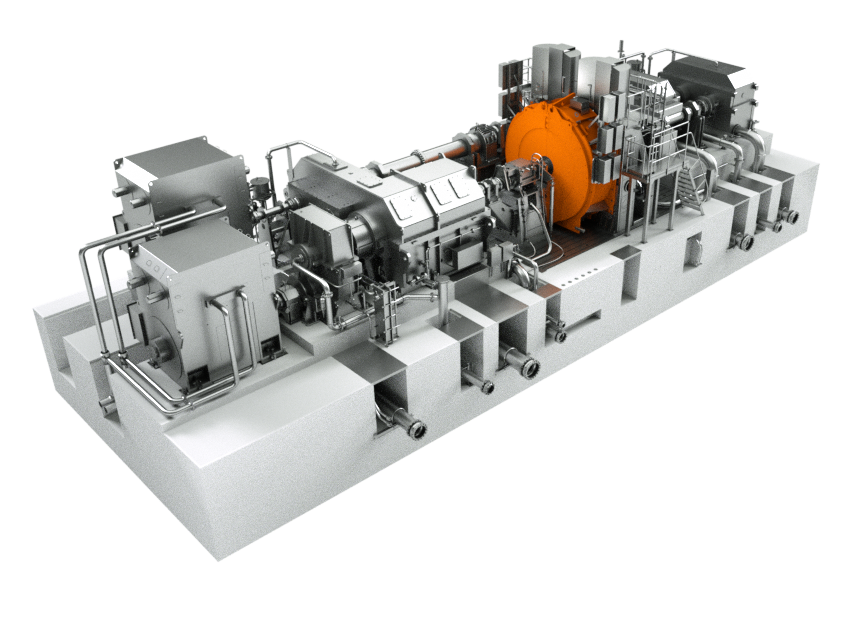

Test rigs for power-gearboxes

RENK has also already implemented test rig solutions for extremely powerful gear units in the multi-megawatt range up to test powers of 100 megawatts.

Innovative power gear units are to decouple the speeds of the driving turbine from the engine fan in jet aircraft and thus enable larger fan diameters and even higher efficiency of future engine generations. In the test rig, these transmissions are not only loaded with torque but, as in reality, with a mixture of different dynamic radial and axial forces.

Test rigs for power-gearboxes

- Test bench for turbine gearboxes of highest power

- Mechanical closed loop + additional 5 DOF load application unit

- Extreme power range

- Extreme control and handling complexity

- Wide range of communication protocols used simultaneously (EtherCAT, PROFIBUS, CAN, SSI, IEEE 1588, DDS)

- Unrivaled reliability and durability

- Master RENK RDDS automation system and measurement acquisition

Test rigs for power-gearboxes

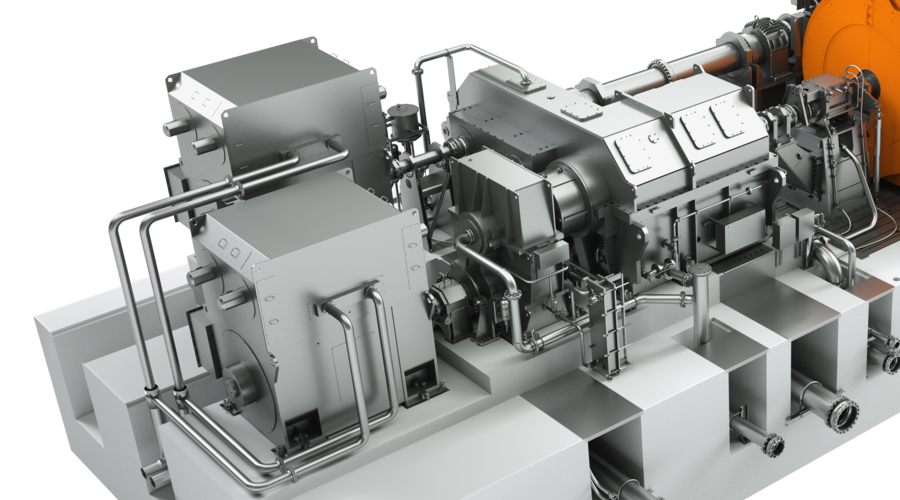

Powerful mechanical closed loop

The test stand is driven by two medium-voltage motors with 11 MW each. Special gear units are used to build up a mechanical tensioning circuit in which the load gearbox introduces the required tensioning power. This tensioning power can be precisely controlled up to a maximum of 100 MW.

Test rigs for power-gearboxes

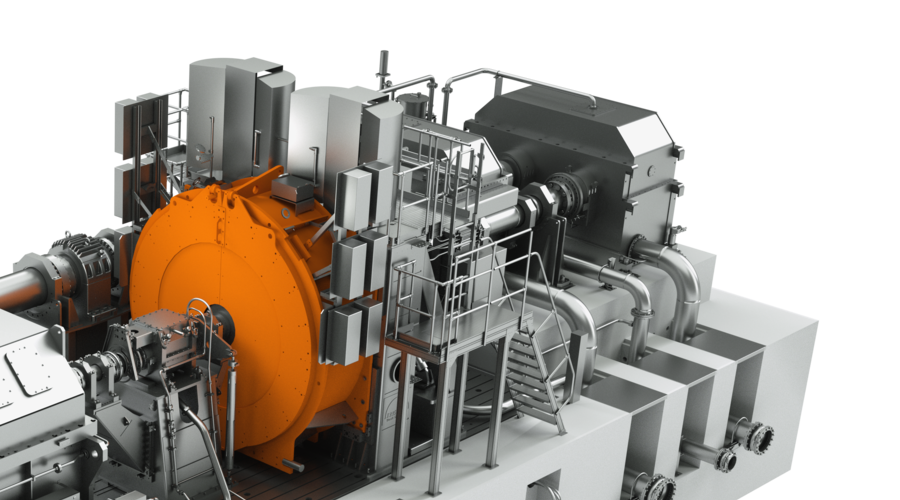

Multi-axis forces and bending moments

An additional load application unit allows all forces occurring in real operation to be simulated in the test rig. In addition to the torque of the motors, this loading unit enables the static and dynamic simulation of transverse and longitudinal forces as well as multi-axis bending moments.

Test rigs for power-gearboxes

Big data

Internal and external measurement technology, safety circuits and building technology provide enormous amounts of data. The RDDS test stand automation provides 600 measuring channels for this purpose, which records and stores all sensor data online. The data relevant for the current test are graphically displayed to the operator at any time and made available for parallel analyses.